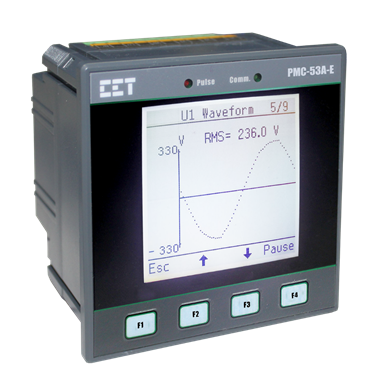

The PMC-53A-E Ethernet Multifunction Meter is CET’s latest offer for the digital power/energy metering market. Housed in a standard DIN form factor measuring 96x96x88mm, it is perfectly suited for industrial, commercial and utility applications requiring direct Ethernet connectivity. The PMC-53A-E features quality construction, multifunction measurements and a large, backlit, Dot-Matrix LCD that is easy to navigate and user friendly. Compliance with the IEC 62053-22 Class 0.5S and ANSI C12.20 Class 0.2 Standards, it is a cost-effective replacement for analog instrumentation and is capable of displaying 4 measurements at once. It also optionally provides an I4 input for Neutral Current Measurement, one 0/4-20mA Analog Input for measuring external transducer signal as well as an Ir Input for Residual Current Measurement. With a standard 100BaseT Ethernet Port and a RS-485 port supporting multiple protocols, the PMC-53A-E can be easily integrated into Energy Management Systems as well as Building and Utility Automation Systems.

Typical Applications

- Industrial, Commercial and Utility Substation Metering

- Building, Factory and Process Automation

- Sub-metering and Cost Allocation

- Retrofit applications with optional Class 0.5 Split-Core CTs

Features Summary

Basic Measurements

- ULN, ULL per phase and Average with Neutral-to-Ground Voltage (Ung)

- Current per phase and Average with calculated Neutral

- P, Q, S, PF per phase and Total

- kWh, kvarh Import / Export / Net / Total and kVAh Total

- Frequency

- Device Operating Time (Running Hours)

- Optional Neutral Current (I4) and Residual Current (Ir) Measurement

Advanced Measurements

- 1-cycle Real-time U & I Waveform Display @ 1s update

- U and I THD, TOHD, TEHD and Harmonics analysis up to 31st

- Current TDD, TDD Odd, TDD Even, K-Factor and Crest Factor

- U and I Unbalance and Phase Angle

- Displacement PF

- Fundamental U, I and P per phase

- Total Fundamental P & Total Harmonic P

- U and I Symmetrical Components

- %kvarh Imp/kWh Imp, %kvarh Exp/kWh Imp for Last Day & Last 30 Days

- 12 Monthly Logs of kWh, kvarh Imp/Exp/Tot/Net, kVAh and kvarh Q1 -Q4

- Interval Energy for kWh/kvarh Imp/Exp and kVAh

- Present, Predicted and Maximum Demands for ULN, ULL, I per phase and Average as well as P/Q/S Total with Timestamp for This Month & Last Month (or Since Last Reset & Before Last Reset)

- Two TOU schedules, each providing

- - 12 Seasons

- - 20 Daily Profiles, each with 12 Periods in 15-minute interval

- - 90 Holidays or Alternate Days

- - 8 Tariffs, each providing the following information

- Total and 3-Phase kWh/kvarh Imp/Exp, kVAh

- P/Q /S Max. Demands

Ease of use

- Large, backlit, Dot-Matrix LCD display with wide viewing angle

- Intuitive user interface

- LED indicators for Energy Pulsing and Communication activities

- Password protected setup via Front Panel, Web Server or PMC Setup

- Easy installation with mounting clips, no tools required

Setpoints

- 9 user programmable setpoints with extensive monitoring parameters including Voltage, Current, Power , PF, Current and Power Demand, Unbalance and THD, etc.

- Configurable thresholds, time delays, DO and Alarm Email triggers

SOE Logs

- 100 events time-stamped to ±1ms resolution

- Setup changes, Setpoint, DI status changes and DO operations

Max./Min. Log

- Max./Min. Log with Timestamp for Real-time measurements such as Voltage, Current, In, I4, Ir, Frequency, P , Q , S, PF, Unbalance, K-Factor, Crest Factor and THD.

- Configurable for This Month/Last Month or Before/Since Last Reset

Freeze Logs

- 60 Daily Freeze Logs for kWh/kvarh/kVAh Total and P/Q/S Max. Demands

- 36 Monthly Freeze Logs for kWh/kvarh/kVAh Total and P/Q/S Max. Demands with Timestamp

Data Recorder (DR)

- 5 Data Recorders of 16 parameters each for Real-time measurements, Harmonics, Energy, Demand, TOU, Pulse Counters, etc.

- Recording interval from 1 minute to 40 days

- Configurable capacity up to a max. of 1145 days (> 3 years) at 15-minute interval for 1 Data Recorder with 16 parameters for HK BEC2018 Compliant Recording

Diagnostics

- Frequency Out-of-Range, Loss of Voltage / Current

- P Direction per phase and Total, Possible incorrect CT Polarity

- Incorrect U & I Phase Sequence

- Disconnection of Residual Current Input

Communications

- One 100BaseT Ethernet Port with RJ45 connector

- One optically isolated RS485 port with baud rate from 1.2kbps to 38.4kbps

- Built-in Web Server for easy data viewing and setup configurations

- Protocol supported: Modbus TCP/RTU, BACnet MSTP, DNP 3.0, HTTP, SMTP, SNTP, TFTP and Ethernet Gateway

Real-Time Clock

- Battery-backed Real-time Clock with 6ppm accuracy (<0.5s per day)

System Integration

- Supported by CET’s PecStar® iEMS

- Easy integration into Building Automation Systems with BACnet MSTP or Modbus RTU and Utility Substation Automation with DNP 3.0

- The on-board password protected Web Server allows complete access to its data and supports the configuration for most of the Setup parameters via a standard web browser

Inputs and Outputs

Digital Inputs

- 4 channels, volt free dry contact, 24VDC internally wetted

- 1000Hz sampling for status monitoring with programmable debounce

- Pulse counting with programmable weight for each channel for collecting WAGES (Water, Air, Gas, Electricity, Steam) information

- Tariff switching based on DI status

Digital Outputs

- 2 Form A Mechanical Relays for alarming and general purpose control Pulse Outputs (Optional)

- 2 Form A Soild State Relays for kWh and kvarh pulsing

Analog Inputs (Optional)

- I4 Current Input for Neutral Current measurement

- Ir Input for Residual Current measurement (CT not included)

- 0/4-20mA DC Input with programmable zero and full scales